Major Reasons for Transformer Failures and How to Avoid Them

Dry type Transformers play a critical role in our electrical infrastructure from industrial plants and data centers to residential grids. They step up or step-down voltage levels, ensuring power is delivered safely and efficiently. However, when a transformer fails, it can lead to costly downtime, equipment damage, and even safety hazards.

Transformer failures are not always sudden; they are often the result of small, overlooked issues that build up over time. Understanding these causes is essential to maintaining efficiency, reducing repair costs, and extending the lifespan of your equipment.

In this article, we’ll explore the major reasons behind transformer failures and provide practical tips on how to prevent them, helping you keep your power systems running reliably for years to come.

Product Category

Dry Type Transformers – Used Dry Type Transformers For Sale

Looking for dry type transformers for sale? Bruce Electric offers our selection of new, reconditioned, and used dry type transformers for sale from top brands including GE, HAMMON, FEDERAL PACIFIC and more. Request a quote today!

Understanding Transformer Failures

A transformer failure occurs when the unit can no longer perform its intended function -typically due to insulation breakdown, electrical faults, or mechanical damage. These failures may be internal, like winding short circuits or oil leaks, or external, such as lightning strikes or overheating due to poor ventilation.

The impact of a failed transformer can be serious: production halts, financial losses, and even power outages. Hence, early identification of risk factors and proactive maintenance are key to ensuring transformer reliability and longevity.

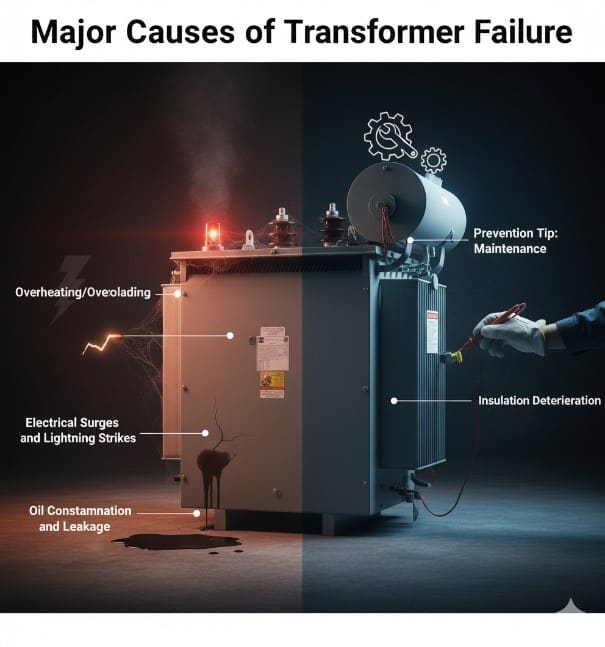

Major Causes of Transformer Failure

Let’s break down the most common reasons why transformers fail and what can be done to mitigate these risks.

1. OVERHEATING AND OVERLOADING

One of the leading causes of transformer failure is overheating. When a transformer operates beyond its designed load capacity for extended periods, the internal temperature rises, damaging insulation materials and accelerating aging.

Overheating typically results from:

• Excessive load or current draw

• Poor ventilation or blocked cooling fans

• Inadequate oil circulation in oil-cooled transformers

According to industry data, every 10°C rise above the rated temperature can cut insulation life in half.

Prevention Tip:

Monitor transformer load levels continuously and ensure proper cooling through fans or radiators. Install temperature sensors to track operating conditions and respond quickly to abnormal heat buildup.

2. INSULATION DETERIORATION

The insulation system is the backbone of transformer reliability. Over time, exposure to heat, moisture, and electrical stress weakens the insulation, leading to short circuits or dielectric failure.

Factors contributing to insulation breakdown include:

• Prolonged thermal stress

• Moisture ingress through seals or vents

• Chemical contamination of transformer oil

Once insulation fails, repair often becomes uneconomical, leading to complete unit replacement.

Prevention Tip:

Conduct insulation resistance tests periodically using a Megger device, and maintain optimal oil quality to protect insulation from moisture.

3. OIL CONTAMINATION AND LEAKAGE

In oil-filled transformers, oil serves as both a coolant and an insulator. When this oil becomes contaminated with moisture, dirt, or dissolved gases, its dielectric strength decreases significantly.

Leakage or oxidation can also lead to sludge formation, further restricting oil circulation and cooling.

Prevention Tip:

Perform regular oil filtration and Dissolved Gas Analysis (DGA). These tests help detect early signs of thermal stress or contamination, allowing timely maintenance before major damage occurs.

4. ELECTRICAL SURGES AND LIGHTNING STRIKES

Transformers are often exposed to electrical surges, especially during switching operations or lightning storms. These high-voltage impulses can cause insulation punctures or winding deformation.

Although surge arresters and grounding systems are designed to protect against such incidents, improper installation or degradation over time can reduce their effectiveness.

Prevention Tip:

Ensure proper grounding and surge protection systems are in place. Conduct periodic inspections of surge arresters, and replace aged components promptly.

5. MANUFACTURING DEFECTS OR DESIGN FLAWS

While less common, manufacturing defects can still lead to premature transformer failure. Poor workmanship, substandard materials, or incorrect winding configurations can compromise performance.

Common examples include:

• Misalignment of cores or windings

• Inadequate insulation clearances

• Faulty brazing or welding joints

Prevention Tip:

Partner only with certified and reputed manufacturers who adhere to international quality standards such as IEEE, IEC, or UL. Bruce Electric, for example, ensures every transformer is rigorously tested before delivery to guarantee reliability.

6. POOR MAINTENANCE PRACTICES

Even the most durable transformer can fail if not maintained properly. Neglecting regular inspections, ignoring oil leaks, or skipping testing routines leads to cumulative damage.

Many failures occur simply because of:

• Lack of routine inspection schedules

• Ignoring abnormal humming or heating

• Delayed replacement of degraded parts

Prevention Tip:

Establish a preventive maintenance plan that includes:

• Monthly visual inspections

• Annual oil and insulation testing

• Thermal imaging for hotspots

• Vibration and sound analysis

A disciplined maintenance routine can prevent up to 70% of avoidable transformer failures.

7. ENVIRONMENTAL AND EXTERNAL FACTORS

Transformers often operate in harsh environments were temperature, humidity, dust, or vibration can accelerate wear. For example, coastal installations may suffer corrosion due to salt air, while dusty environments can block cooling ducts.

Prevention Tip:

Install transformers in clean, well-ventilated enclosures. Consider IP-rated protection housings for outdoor or industrial use and apply protective coatings where necessary.

How to Prevent Transformer Failures

Preventing transformer failures involves more than fixing issues it’s about creating a culture of predictive and preventive maintenance. Below are best practices to ensure reliability and efficiency.

1. REGULAR PREVENTIVE MAINTENANCE

Routine testing and inspection can identify early warning signs long before a failure occurs.

Maintenance should include:

• Oil testing: For acidity, moisture, and gas content

• Insulation resistance measurement: To detect degradation

• Load balancing checks: To prevent uneven heating

• Cooling system inspection: To ensure proper temperature control

Following a structured maintenance schedule reduces downtime and extends transformer life expectancy.

2. USE OF QUALITY COMPONENTS AND RELIABLE SUPPLIERS

The quality of materials directly affects transformer performance. Inferior components, such as poor-grade steel or insulation paper, can cause premature aging or breakdown.

Bruce Electric, for example, uses UL-listed and ISO-certified components, ensuring safety and long-term reliability. By partnering with trusted suppliers, you not only enhance transformer durability but also minimize the risk of sudden failures.

3. CONTINUOUS MONITORING AND SMART DIAGNOSTICS

Advancements in technology have made real-time monitoring systems essential for modern transformer management. These systems track temperature, oil levels, vibration, and voltage fluctuations.

Prevention Tip:

Install sensors and connect them to centralized control systems. Set threshold alerts for temperature, load, and oil quality to detect abnormalities early.

4. PROPER INSTALLATION AND LOAD MANAGEMENT

Incorrect installation or uneven load distribution can lead to long-term stress on a transformer.

Installation Best Practices:

• Ensure balanced phase loading

• Maintain proper grounding

• Avoid over-tightening of electrical connections

• Verify alignment and secure mounting

A properly installed and balanced transformer operates efficiently and lasts significantly longer.

Signs of a Failing Transformer

Recognizing the early symptoms of transformer distress can prevent catastrophic breakdowns. Watch out for:

• Unusual humming or vibration

• Discoloration or leakage of oil

• Excessive temperature rise

• Burning smell or smoke

• Visible bulging of the tank or bushings

If any of these signs appear, conduct immediate diagnostic testing and isolate the transformer if necessary.

Conclusion

Transformer failures may seem sudden, but they’re almost always the result of preventable issues – overheating, oil contamination, insulation wear, or poor maintenance. By understanding these causes and taking proactive measures, businesses can save significant time and money while ensuring power reliability.

Whether through routine maintenance, smart monitoring systems, or quality transformers, prevention is always more cost-effective than repair.

Bruce Electric continues to be a trusted partner for durable, energy-efficient transformers designed to meet the most demanding industrial and commercial applications.

FAQs on Transformer Failures

Q1: What is the most common problem with transformers?

A: The most common problem is overheating, usually caused by overloading, poor ventilation, or insulation breakdown.

Q2: How to tell if a transformer is bad?

A: Signs include unusual humming, excessive heat, oil leakage, burning smell, or no output voltage during testing.

Q3: What is the short circuit test of a transformer?

A: It’s a test performed with the secondary winding shorted to measure copper losses and determine the transformer’s equivalent impedance under load.

Q4: How many ohms should a transformer read?

A: Resistance varies by type and size, but primary winding usually reads tens to hundreds of ohms, while secondary winding shows very low resistance (below 1 ohm).

Q5: What is a no-load test on a transformer?

A: It’s a test done with the secondary winding open to measure core (iron) losses and magnetizing current when the transformer runs without load.