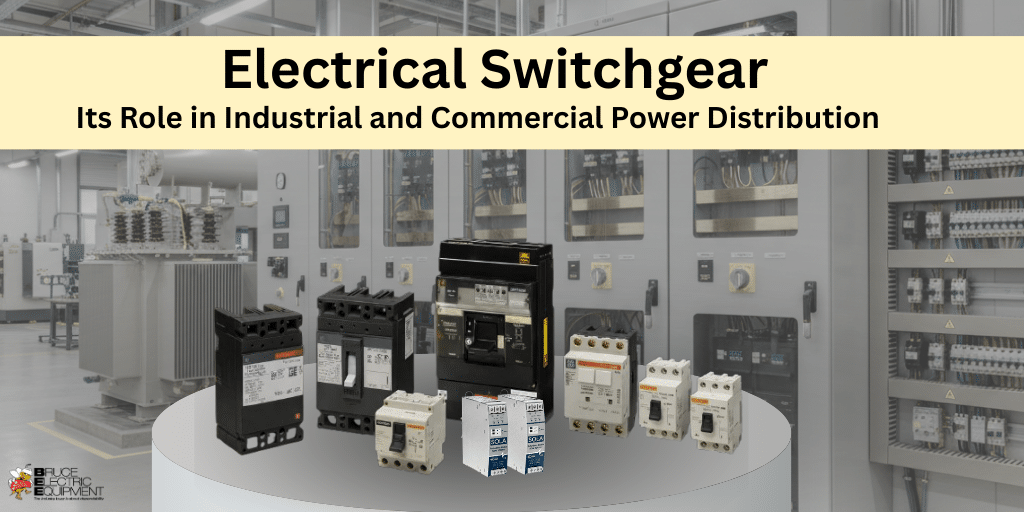

Electrical Switchgear and Its Role in Industrial and Commercial Power Distribution

Modern facilities depend on reliable, continuous, and safe electrical power. From manufacturing plants and hospitals to commercial office buildings and data centers, electrical switchgear is a critical part of the power distribution system that protects equipment, isolates faults, and ensures operational continuity.

In this guide, we explain what electrical switchgear is, how it works, the types of electrical switchgear, key switchgear components, and how it fits into industrial power distribution systems. We’ll also clarify the difference between switchgear vs switchboard vs panelboard, so you can select the right power distribution equipment for your application.

What Is Electrical Switchgear?

Electrical switchgear is a combination of electrical disconnect switches, fuses, or circuit breakers used to control, protect, and isolate electrical equipment.

Its primary functions are:

• Interrupt fault currents

• Isolate equipment for maintenance

• Control power flow

• Protect downstream equipment from overloads and short circuits

• Enhance system reliability and safety

In industrial and commercial environments, switchgear acts as the “nerve center” of power control managing the distribution of electricity from transformers to panels, motor control centers, and critical loads.

How Electrical Switchgear Works

Switchgear operates by detecting abnormal electrical conditions such as short circuits, overloads, or ground faults and automatically interrupting the circuit to prevent equipment damage or fire hazards.

Here’s a simplified breakdown of the process:

1. Power enters the system through a transformer.

2. Protective relays monitor voltage and current levels.

3. If a fault is detected, the circuit breaker trips.

4. The affected section is isolated while the rest of the system remains operational (in properly designed systems).

This selective coordination is essential in commercial and industrial facilities where downtime directly impacts productivity and revenue.

Types of Electrical Switchgear

Switchgear is classified primarily by voltage level. Understanding the differences helps engineers and facility managers select the correct system for their application.

Low Voltage Switchgear (Up to 1,000V)

Common in commercial buildings and light industrial facilities.

Typical applications:

• Retail spaces

• Small manufacturing units

• Educational institutions

Key features:

• Molded case or air circuit breakers

• Compact footprint

• Modular design

• Often integrated with panel boards

Medium Voltage Switchgear (1kV-36kV)

Medium voltage switchgear is widely used in industrial plants, utility substations, and large commercial facilities.

Applications:

• Oil & gas facilities

• Mining operations

• Large infrastructure projects

Advantages:

• Handles higher fault currents

• Supports distributed industrial loads

• Often uses vacuum or SF6 circuit breakers

• Enhanced protection and monitoring capabilities

Medium voltage systems are common in heavy-duty industrial power distribution networks where reliability is non-negotiable.

High Voltage Switchgear (Above 36kV)

High voltage switchgear is primarily used in transmission networks and large-scale substations.

Applications:

• Utility grids

• Power generation plants

• Large substations

These systems are engineered for extremely high fault currents and typically include gas-insulated or air-insulated configurations.

Key Switchgear Components

Understanding switchgear components helps in evaluating performance, safety, and maintenance requirements.

Core components include:

1. Circuit Breakers

The primary protective device that interrupts fault currents. Types include:

• Air Circuit Breakers (ACB)

• Vacuum Circuit Breakers (VCB)

• SF6 Circuit Breakers

2. Protective Relays

Monitor electrical parameters and signal breakers to trip during abnormal conditions.

3. Busbars

Conductors that distribute power within the switchgear assembly.

4. Disconnect Switches

Provide visible isolation for maintenance and safety.

5. Instrument Transformers

Used for measurement and protection (Current Transformers and Voltage Transformers).

6. Enclosures

Metal-clad or metal-enclosed structures designed to contain arc flash and protect operators.

High-quality components significantly reduce maintenance costs and improve system longevity.

The Role of Electrical Switchgear in Industrial Power Distribution

In industrial power distribution, switchgear is not optional it is foundational.

Here’s how it supports operations:

1. Fault Protection

Prevents catastrophic equipment damage and reduces fire risk.

2. Operational Continuity

Selective coordination ensures only the faulty section shuts down—not the entire plant.

3. Equipment Protection

Protects transformers, motors, drives, and sensitive electronics from overloads and short circuits.

4. Worker Safety

Arc-resistant switchgear reduces risk during electrical faults.

5. Scalability

Modular systems allow facilities to expand capacity without replacing entire systems. For industries where downtime costs thousands of dollars per hour, switchgear directly impacts profitability.

Switchgear vs Switchboard vs Panel board: What’s the Difference?

This is one of the most common questions in commercial electrical planning.

Electrical Switchgear

• Handles higher voltages and fault currents

• Includes breakers, relays, disconnects

• Used in industrial and large commercial systems

• Built for fault interruption and system protection

Switchboard

• Distributes power to branch circuits

• Lower interrupting ratings than switchgear

• Common in commercial buildings

Panel board

• Supplies branch circuits in residential or light commercial settings

• Lower capacity and simpler configuration

In summary:

Switchgear = protection and high-capacity control

Switchboard = distribution

Panel board = localized branch distribution

Choosing the wrong equipment can result in undersized protection and compliance issues.

Selecting the Right Electrical Switchgear

Choosing the right electrical switchgear starts with understanding your facility’s power requirements and long-term operational goals. First, identify your system voltage low voltage for most commercial buildings, or medium voltage for larger industrial operations. Next, confirm the available fault current and ensure the switchgear’s short-circuit rating safely exceeds it to prevent equipment damage during a fault. Consider your load types (motors, HVAC systems, data equipment, production machinery) and whether future expansion is planned, as scalable switchgear can save significant upgrade costs later. Installation environment also matters outdoor, dusty, or high-moisture locations may require specialized enclosures. Finally, verify compliance with NEC, UL, IEEE, and ANSI standards to ensure safety and code approval. By evaluating these factors upfront, facility managers and engineers can select switchgear that improves reliability, reduces downtime, and protects valuable electrical infrastructure.

Integration with Other Power Distribution Equipment

Electrical switchgear does not operate in isolation. It integrates with:

• Automatic Transfer Switches (ATS)

• Circuit breakers

In properly engineered systems, transformers step down voltage, switchgear protects and controls it, and panel boards distribute it to end-use loads. For commercial and industrial facilities, coordination between transformers and switchgear is critical for safe, efficient operation.

FAQs

Q1) What is a distribution switchgear?

A) Distribution switchgear controls and protects electrical circuits by safely distributing power from transformers to panels and connected loads.

Q2) What type of wire is used for switchgear?

A) Switchgear uses insulated copper or aluminum conductors, with copper or aluminum busbars for higher current capacity.

Q3) What is HT and LT switchgear?

A) 1. HT switchgear is used in high-voltage systems above 1kV for industrial and utility applications.

2. LT switchgear operates up to 1kV and is used in commercial and low-voltage power distribution.

Q4) What are the benefits of switchgear?

A) Switchgear improves safety, protects equipment from faults, reduces downtime, and ensures reliable power distribution.

Q5) How to test switchgear?

A) Switchgear is tested using insulation resistance tests, breaker timing tests, relay checks, and functional operation inspections.

Conclusion

Electrical switchgear is essential to modern industrial and commercial power distribution, serving as the critical protection and control layer between transformers and end-use equipment. From low voltage commercial systems to medium and high voltage industrial applications, properly specified switchgear improves safety, ensures fault isolation, and protects valuable assets from costly damage and downtime. Whether you require low voltage switchgear integrated with dry-type transformers, or circuit breakers for expanding industrial capacity, sourcing equipment from a reliable U.S. supplier ensures compliance, performance, and rapid availability.